When you receive a package that’s beautifully designed and custom-made to fit your purchase, it’s hard not to feel a little extra excited. That’s why custom paper packaging is becoming increasingly popular – it offers businesses the chance to wow customers with unique packaging that captures their brand perfectly. By using printing techniques, businesses can create practical yet visually stunning designs that ensure the product inside is protected and presented in the best possible way. In this guide, Cowin Packaging take you through the different techniques used, how to choose the right one for your brand, and offer some tips on creating the kind of packaging that’ll leave your customers overjoyed.

Let’s dive into the different printing techniques for custom paper packaging!

A. Digital Printing

1. What is it?

Digital printing is a modern way of printing digital files directly onto paper and cardboard using inkjet and laser printing technology to produce high-quality prints.

2. Benefits:

This method is cost-effective, flexible, and has shorter production times. As a bonus, it allows for personalized designs and the printing of variable data.

3. Where is it used?

Digital printing can be used for a range of custom paper packaging designs for branding, gift boxes, promotional materials, and packaging inserts.

4. Things to remember:

Ensure the artwork is in CMYK format and has a high resolution, remember to consider the size, placement, and color of the graphic.

5. Quality control:

To maintain consistent quality, color calibration, high-quality substrates, and proper maintenance of printers all play a significant role in producing high-quality digital prints.

B. Offset Printing

1. What is it?

Offset printing is a traditional printing process transferring ink from a printing plate to a rubber blanket, and then to the substrate. It’s best for high-volume production runs of custom paper packaging.

2. Where is it used?

Offset printing is often used for high-volume production runs of retail packaging and shipping boxes.

3. Things to remember:

Consider ink coverage, print registration, and the use of spot colors or gradients. Like digital printing, ensure the artwork is in high resolution and the proper format.

4. Quality control:

A reliable way to ensure top quality is to use color-matching software, regular maintenance of the printing press, and frequent quality checking.

C. Flexographic Printing

1. What is it?

The method involves the use of flexible printing plates and a rotating cylinder to transfer ink to the substrate, making it optimal for printing on thin materials such as paper and plastic.

2. Where is it used?

Flexographic printing can be used for grocery bags, food packaging, and product branding.

3. Things to remember:

Consider ink coverage, print registration, and the use of spot colors or gradients. Ensure that the artwork is in high resolution and the proper format.

4. Quality control:

Ensure you adhere to quality control measures like the use of color-matching software, regular maintenance, and quality checks to produce high-quality flexographic prints.

D. Gravure Printing

1. What is it?

Gravure printing uses an engraved cylinder to transfer ink to the substrate, making it optimal for high-end product packaging and promotional materials.

2. Where is it used?

Gravure printing is best for creating high-quality images and text and is commonly used for high-end product packaging and promotional materials.

3. Things to remember:

Consider ink coverage, print registration, and the use of gradients or detailed images. Like the other printing methods, ensure that the artwork is in high resolution and the proper format.

4. Quality control:

To maintain quality, use color-matching software, proper maintenance, and regular quality checks.

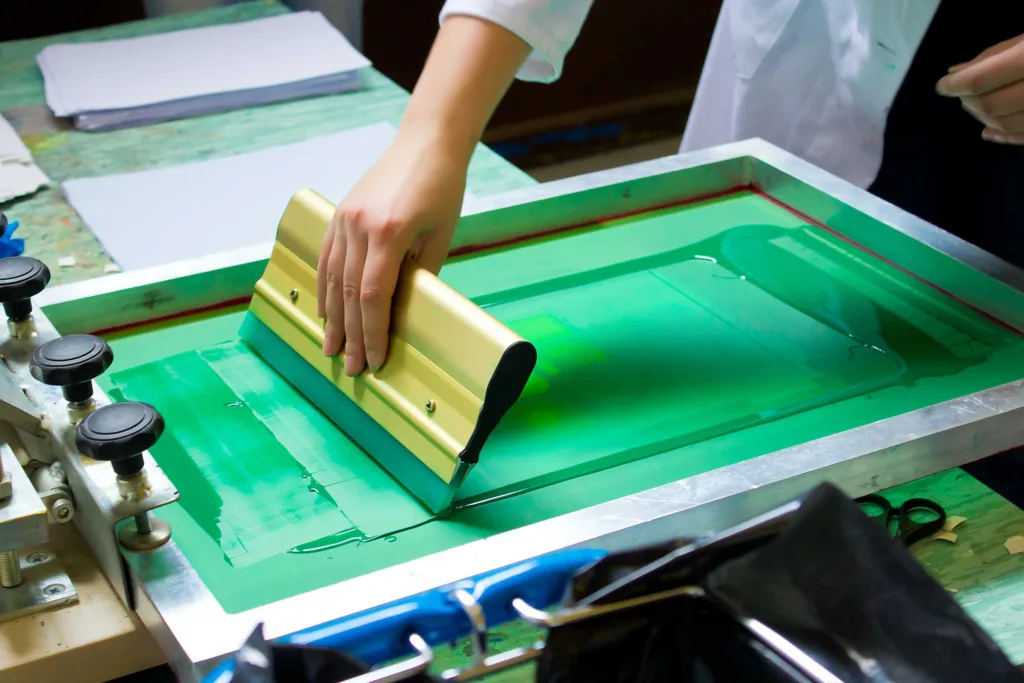

E. Screen Printing

1. What is it?

Screen printing uses a stencil and mesh screen to transfer ink onto the substrate, making it an excellent option for custom paper packaging.

2. Where is it used?

Screen printing is commonly used for branding, gift boxes, and promotional materials.

3. Things to remember:

Consider ink coverage, print registration and the use of spot colors. Artwork should be in vector graphics format with high resolution.

4. Quality control:

High-quality inks, regular maintenance, and quality checks are essential for maintaining consistent high-quality screen prints.

Design Considerations for Custom Paper Packaging

A. Material Selection

When designing custom paper packaging, choosing the right material is critical in ensuring the package provides adequate protection while complementing the product’s branding. Here are four materials commonly used in custom paper packaging.

1. Grey Cardboard:

Cardboard is a versatile and cost-effective material used in creating custom paper packaging. It is the go-to material for product packaging, display boxes, and gift boxes.

2. Paperboard:

Paperboard is another cost-effective but less robust material used in custom paper packaging. It is ideal for packaging applications that require a lightweight and durable solution.

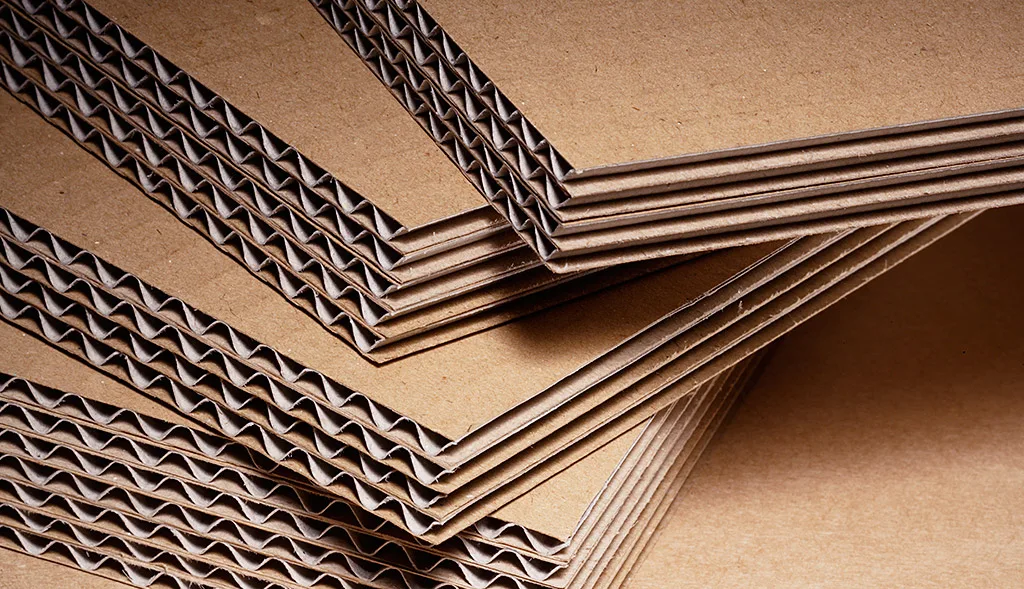

3. Corrugated Board:

Corrugated board is a thick and robust material with fluted paper between two cardboard layers. This material is ideal for shipping boxes and bulky product packaging.

4. Kraft Paper:

Kraft paper is an eco-friendly and recyclable material used in custom paper packaging. It is an ideal solution for product branding and eco-friendly packaging.

B. Printing Inks

1. CMYK:

CMYK (Cyan, Magenta, Yellow, Key/Black) is a color model commonly used in full-color printing. It is the standard color model used in most digital printing presses.

2. Pantone Colors:

Pantone colors are a color space used to specify standard colors that printers can reliably reproduce. They provide a more accurate color representation and are commonly used in offset printing.

C. Finishing Techniques

Finishing techniques can enhance the durability and aesthetics of custom paper packaging. Here are some common finishing techniques used in custom paper packaging:

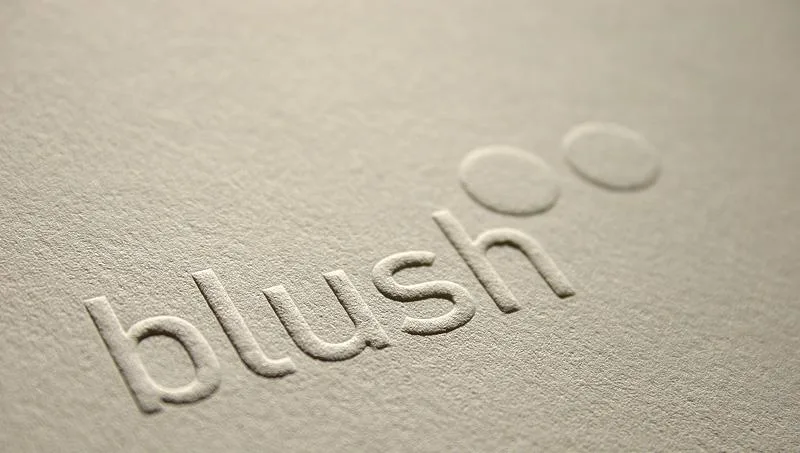

1. Embossing:

Embossing involves creating a raised or depressed design on the surface of the packaging. It adds a unique texture and depth to the printed design.

2. Foil Stamping:

Foil stamping involves the transfer of metallic foil onto the surface of the packaging. It adds a luxurious and eye-catching effect to the design.

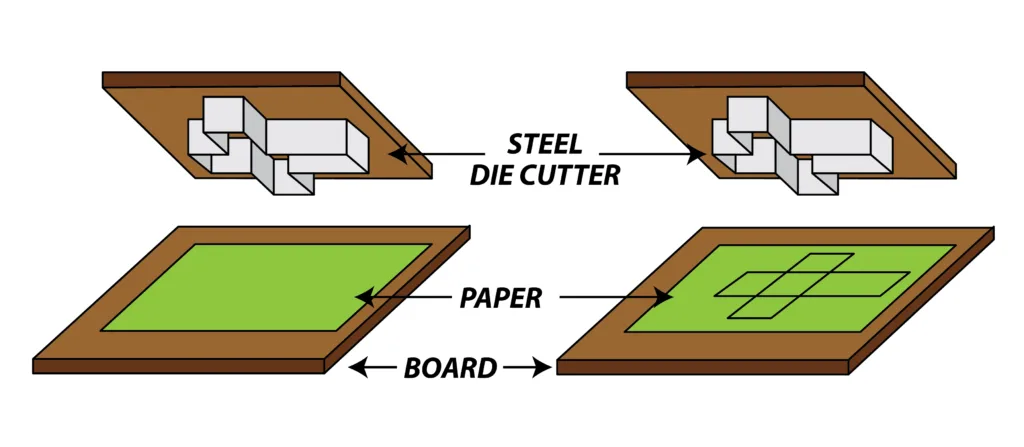

3. Die-cutting:

Die-cutting involves cutting the package into a specific shape to enhance its visual appeal. It is commonly used in custom packaging to make the product stand out on shelves.

4. Spot UV Coating:

Spot UV coating is a finishing technique that involves applying a high-gloss varnish to a specific part of the package design, creating a contrast between matte and shiny texture.

5. Glossy and Matte Finishing:

Glossy and matte finishing are popular finishing options that provide a shiny or non-shiny surface to the packaging. Glossy finishes are ideal for a more vibrant, eye-catching design, while matte finishes offer a more subtle, refined look.

6. PMS Colors:

PMS (Pantone Matching System) colors are a set of standardized colors used in printing. Choosing PMS colors allows for more accurate color matching and consistency across different printing mediums, making it ideal for branding and marketing purposes.

Tips for Creating Effective Custom Paper Packaging

Creating effective custom paper packaging is essential in ensuring that your brand stands out from the crowd. Here are some tips to help you create effective custom paper packaging:

A. Consistent Branding:

Ensure that your custom paper packaging effectively communicates your brand identity by using the right fonts, colors, and design elements that align with your brand.

B. Product Protection:

Custom paper packaging should provide adequate protection to the product it contains. Consider the type of product being packaged and the packaging material to ensure optimum protection.

C. Customer Experience:

Creating an excellent customer experience is vital in customer retention. Create custom paper packaging that is easy to open and handle, and includes product information, special offers, or other extras that add value for customers.

D. Retail Packaging:

Retail packaging should be designed with shelf appeal in mind. It should create a positive first impression and stand out from competing brands on the shelf.

Frequently Asked Questions

A. What printing process is used for printing packaging and boxes?

The printing process used for printing packaging and boxes varies depending on the type of material, design, and printing technology used. Some common printing processes include offset, digital, flexography, gravure, and screen printing.

B. What printing method is most effective in packaging?

The most effective printing method in packaging will depend on the specific project requirements, such as the type of packaging materials, the color scheme, and the intended use of the packaging. Generally, flexography printing is preferred for large production runs, while digital printing is useful for small, customized runs.

C. How are packaging boxes printed?

Packaging boxes are typically printed using the offset or flexography printing process, depending on the material and design.

D. What printing method is used on cardboard?

Cardboard can be printed using a variety of printing methods, including offset and flexography printing. The printing process will depend on the specific project requirements and the capabilities of the printing technology.

E. What do you need to consider when creating a box packaging design?

When creating a box packaging design, there are several factors to consider, such as the size and shape of the box, the printing method and materials to be used, the branding and marketing goals, and any specific regulatory requirements.

F. What paper is used for packaging boxes?

Packaging boxes are typically made from a range of paper materials, such as corrugated board, kraft paper, and coated paper.

G. What is CMYK printing?

CMYK printing is a four-color printing process that uses cyan, magenta, yellow, and black inks to create a wide range of colors.

H. What is Pantone printing?

Pantone printing, also known as spot color printing, uses premixed ink colors to create specific Pantone colors.

I. Is it better to print in CMYK or Pantone?

The choice between CMYK and Pantone printing will depend on the specific project requirements and the desired color accuracy. CMYK is useful for creating a wide range of colors, while Pantone inks provide precise color matching.

J. How can I match Pantone to CMYK?

Pantone colors can be matched to CMYK colors using specialized software or by requesting a printed swatch book from a printing company.

K. Can you use Pantone for print?

Yes, Pantone colors can be used for print, and are commonly used for branding and marketing materials where color accuracy is important.

L. When should you use Pantone colors?

Pantone colors should be used when precise color matching is required, or for branding and marketing materials where consistency is essential.

M. What is hot stamping process?

Hot stamping is a printing process that uses a heated die to transfer a foil or metallic finish onto a surface.

N. What is the difference between hot stamping and cold stamping?

The main difference between hot stamping and cold stamping is the temperature of the die. Hot stamping uses a heated die, while cold stamping uses a non-heated die.

O. What is the difference between hot stamping and pad printing?

The main difference between hot stamping and pad printing is the printing method. Hot stamping uses a heated die to transfer the finish, while pad printing uses a silicone pad to transfer ink onto the surface.

P. What does spot UV finish mean?

Spot UV finish refers to a glossy, raised finish that is applied to specific areas of a printed surface.

Q. Is spot UV the same as spot varnish?

Spot UV and spot varnish are similar in that they both refer to a glossy finish applied to specific areas of a printed surface. However, spot UV has a raised texture, while spot varnish is a smooth finish.

R. What is the difference between debossing and foil?

Debossing refers to the process of creating an indented or sunken area in a surface, while foil refers to a metallic or colored sheet that is stamped onto the surface.

If you need customized packaging advice or solution, hope our rich experience can help you!

Contact with us to get a good quotation and free sample: hi@cowinpackaging.com

Or tell us your needs via the simple form: Click me